CIRCUIT BREAKER OPERATIONS FUNDAMENTALS

4 students

Crown ERAM Semi-Truck

4 hours

This hands-on portion follows the CB Fundamentals class. There are over 15 different electrical apparatus (CB’s, Switches, etc) on the Crown ERAM Semi-Truck used to demonstrate and perform general operational functions.

OBJECTIVE

This is the hands-on portion of the breaker fundamentals class. Student will operate and perform fundamental inspection and maintenance on various pieces of equipment. This course is NOT designed to make them technician that can troubleshoot and repair the equipment.

COURSE CONTENT

- Low and Medium Voltage classes of breakers

- Breaker systems and subsystems and how they fail

- Lubrication technology & Insulation failures

- How to maintain a breaker

- Breaker Testing: Utilizing an insulation resistance tester (Megger)

- Breaker Testing: Utilizing a DLRO,

- Discussion of Primary and Secondary Trip testing

- Interlocks and why you should not defeat them

- The three ways to trip a breaker

- Task Specific Training

- How to protect yourself – Safe Work Habits.

- Body position

- Safest location

- Step before and after operating equipment

- Equipment indicators (semaphores)

- Switching Safety

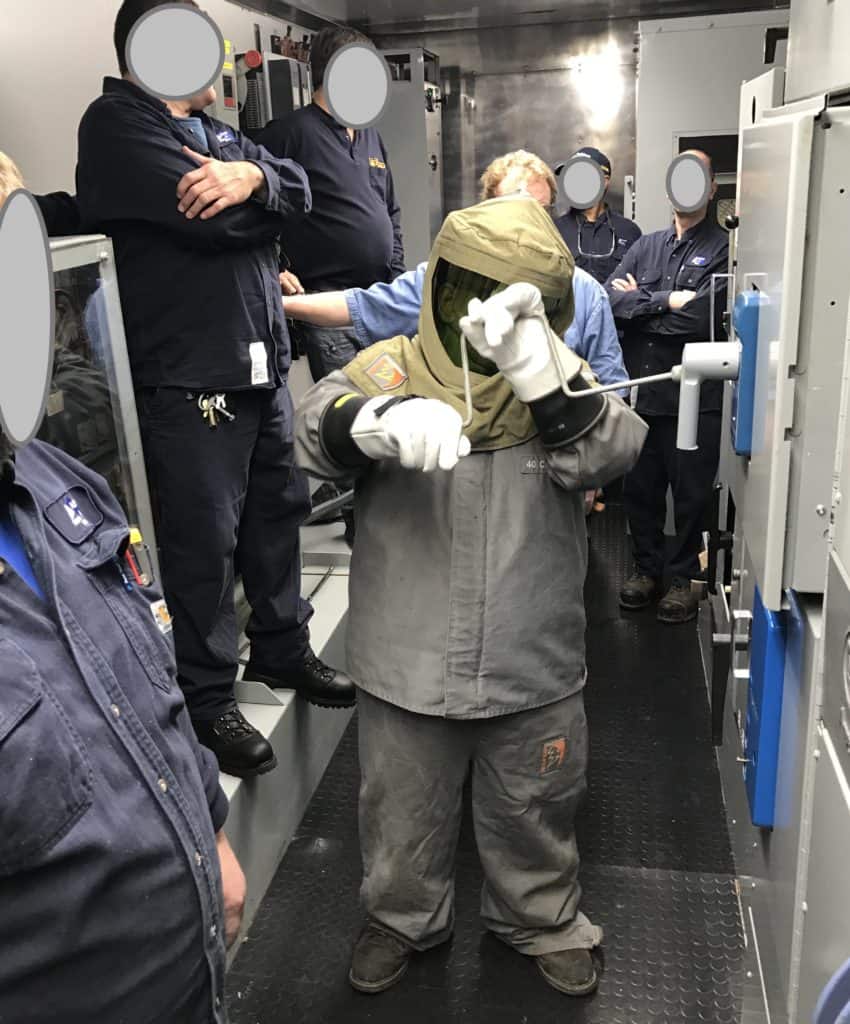

- Dress in 40 Calorie Flash Suit and “Rack out” breakers (depending on Covid)

- Use of Personal Grounds & Hot Sticks

- Interlocks – Passive and Active

- Physiological effects of performing high-risk tasks and “suiting up”

(Semi-truck requires 240 Volt single phase 60 Amp service or can run on generator for an additional charge) The duration of the course depends on student participation. Four-hour course only allows time for 1 student to operate each piece of equipment. 8-hour course allows for every student to operate every piece of equipment.

Our team is

Ready to help!

Crown ERAM’s experienced engineering team detects any issues and will develop a new design parts to advance current capacity of the system.

With proper maintenance, industrial circuit breakers can last for decades. Crown ERAM’s technicians thoroughly inspect your switchgear with all applicable tests.

We test all varieties, sizes, and types of motors, effective in all electrical fault zones for reliability, quality assurance, trending, or fault-zone diagnosis

We scan your equipment functionality safely and quickly. Our Ultrasound non-destructively detects partial discharge and electrical corona while the Thermographic Survey measures passive infrared radiation without down time.

Crown ERAM provides industry-compliant safety education with documented hands-on on-site and performance-based training that is readily available at any location.

We disassemble the machinery, clean components, and replace worn-out parts. It is then reassembled and re-tested. Our machine shop fabricates replacement parts if necessary.